-

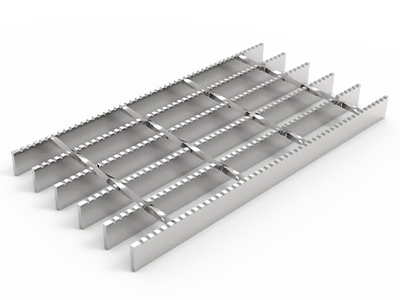

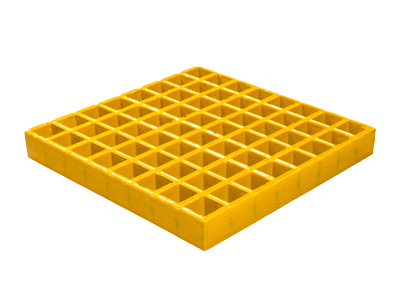

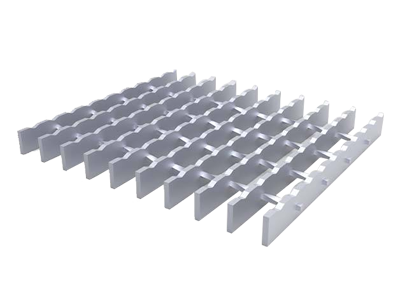

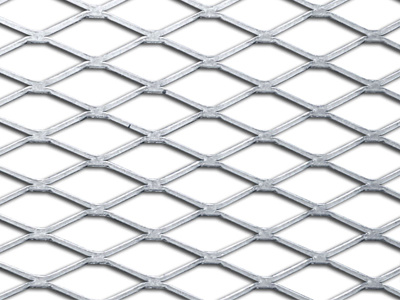

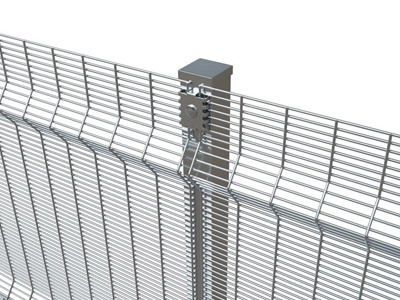

Grating Series

View Products

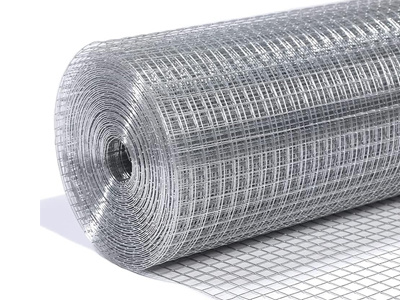

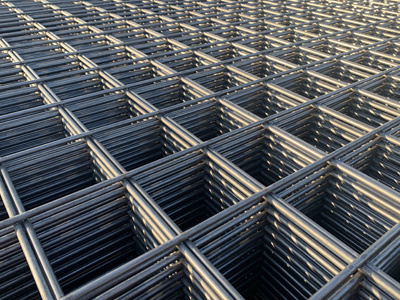

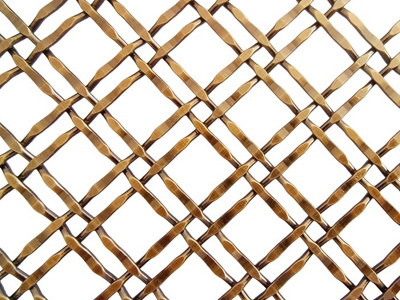

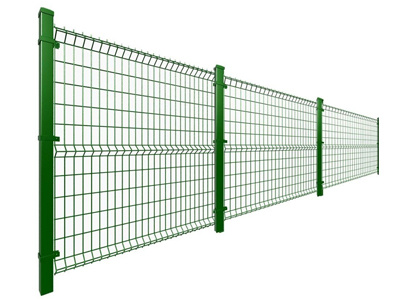

Wire Mesh Series

View Products

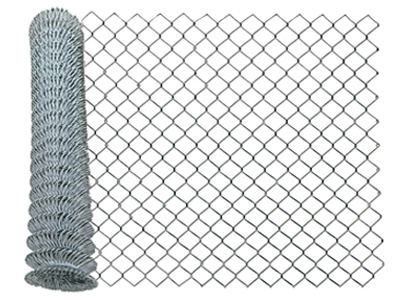

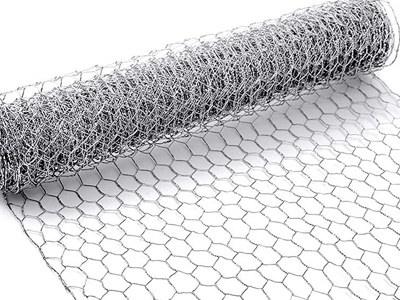

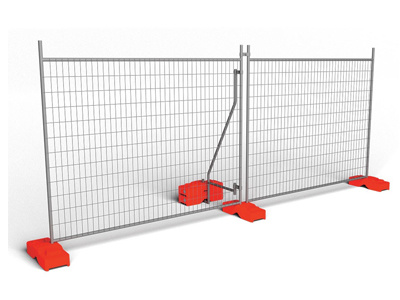

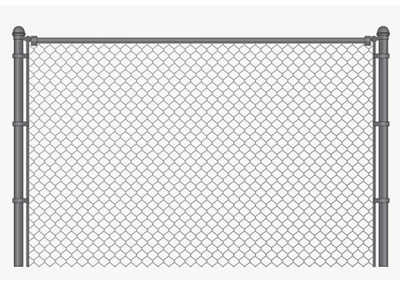

Wire Mesh Fence

View Products

Barbed Wire Series

View Products

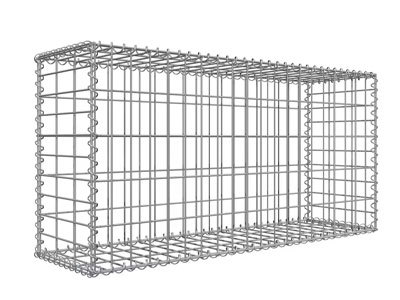

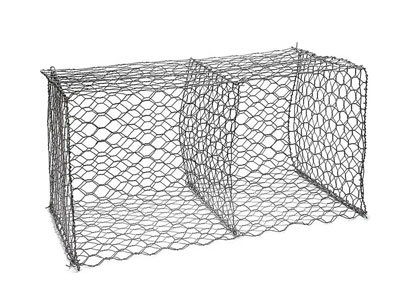

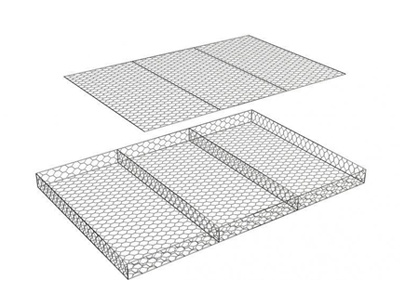

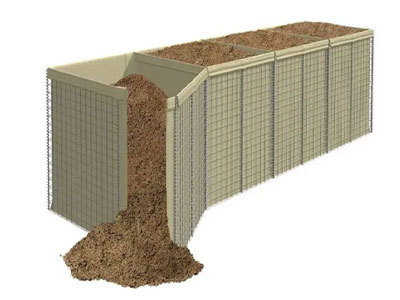

Gabion Basket Series

View Products

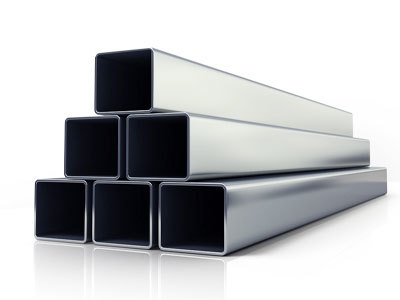

Steel Pipe Series

View Products

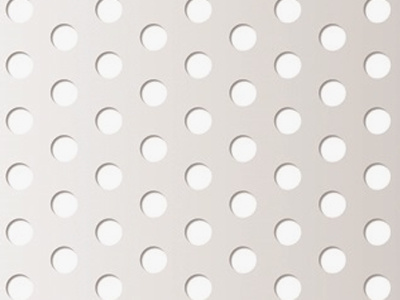

Steel Sheet Series

View Products

Steel Coil Series

View Products

-

-

-

The Critical Role of Galvanized Steel Sheets in Industrial Applications

Jan 01,2026

The Critical Role of Galvanized Steel Sheets in Industrial Applications

Table of Contents

1. Introduction to Galvanized Steel Sheets

2. What is Galvanized Steel?

3. Manufacturing Process of Galvanized Steel Sheets

4. Benefits of Using Galvanized Steel Sheets in Industry

- 4.1 Corrosion Resistance

- 4.2 Durability and Longevity

- 4.3 Cost-Effectiveness

5. Applications of Galvanized Steel Sheets

- 5.1 Construction Industry

- 5.2 Automotive Industry

- 5.3 Agricultural Applications

6. Future Trends in Galvanized Steel Sheets

7. Conclusion

8. Frequently Asked Questions

Introduction to Galvanized Steel Sheets

Galvanized steel sheets have emerged as a crucial material in industrial applications, offering a unique combination of strength and resistance to environmental factors. These sheets are commonly used in the manufacturing of various products and structures, showcasing their versatility. In this article, we will delve into the importance of galvanized steel sheets, exploring their benefits, applications, and future trends.

What is Galvanized Steel?

Galvanized steel is a type of steel that has been coated with a layer of zinc to protect it from corrosion. The galvanization process involves immersing steel in molten zinc, creating a robust barrier against environmental elements. This protective layer ensures that the underlying steel remains intact, which is particularly vital in harsh industrial settings. The use of galvanized steel sheets is widespread across various sectors, thanks to their outstanding protective properties and strength.

Manufacturing Process of Galvanized Steel Sheets

The manufacturing process of galvanized steel sheets typically involves several steps that ensure a high-quality product:

1. **Preparation**: The steel surface is cleaned to remove any rust or contaminants, which is essential for proper adhesion of the zinc coating.

2. **Galvanization**: The clean steel sheets are dipped into a bath of molten zinc. This process is known as hot-dip galvanization and provides a thick zinc coating.

3. **Cooling**: After the galvanization process, the sheets are cooled to solidify the zinc coating.

4. **Inspection**: Finally, the finished products are inspected for quality and consistency to ensure they meet industry standards.

This meticulous manufacturing process results in galvanized steel sheets that are durable and resistant to corrosion, making them ideal for various industrial applications.

Benefits of Using Galvanized Steel Sheets in Industry

The use of galvanized steel sheets in industrial applications is driven by numerous advantages that enhance their appeal. Below, we explore some key benefits:

Corrosion Resistance

One of the primary benefits of galvanized steel sheets is their exceptional corrosion resistance. The zinc coating forms a protective barrier that prevents moisture and oxygen from reaching the steel, significantly reducing the risk of rust. This characteristic is particularly beneficial in industries where the materials are exposed to harsh weather conditions or corrosive agents.

Durability and Longevity

Galvanized steel sheets are known for their remarkable durability. They can withstand mechanical stress, impact, and extreme temperatures, making them suitable for heavy-duty applications. The longevity of these sheets translates to lower replacement costs over time, providing a solid return on investment.

Cost-Effectiveness

While the initial cost of galvanized steel sheets may be higher than other materials, the long-term savings in maintenance and replacement make them a cost-effective choice. Their durability ensures that they remain functional for years without requiring frequent repairs, ultimately reducing operational costs.

Applications of Galvanized Steel Sheets

Galvanized steel sheets have found their way into various industrial sectors. Here are some notable applications:

Construction Industry

In construction, galvanized steel sheets are widely used for roofing, siding, and framing. Their corrosion resistance and strength make them ideal components for buildings that require longevity and minimal maintenance. Additionally, they are often used in the manufacturing of metal buildings and structures.

Automotive Industry

The automotive industry utilizes galvanized steel sheets for body panels and other components. The corrosion resistance of these sheets ensures the longevity of vehicles, while their lightweight nature contributes to fuel efficiency.

Agricultural Applications

In agriculture, galvanized steel is used for fencing, storage tanks, and equipment. The ability to withstand outdoor conditions without deteriorating makes galvanized steel sheets a popular choice among farmers and agricultural businesses.

Future Trends in Galvanized Steel Sheets

As industries continue to evolve, the demand for galvanized steel sheets is expected to grow. Innovations in galvanization techniques and advancements in steel manufacturing will likely enhance the quality and sustainability of these materials. Additionally, the push for environmentally friendly solutions may lead to the development of new coatings that reduce environmental impact while maintaining the protective qualities of galvanized steel.

Conclusion

In conclusion, galvanized steel sheets play a pivotal role in industrial applications, offering significant benefits such as corrosion resistance, durability, and cost-effectiveness. Their versatile nature allows them to be utilized across various sectors, from construction to automotive and agriculture. As we look to the future, advancements in technology will only further enhance their applications and benefits, solidifying their importance in the industrial landscape.

Frequently Asked Questions

1. What makes galvanized steel sheets corrosion-resistant?

Galvanized steel sheets are coated with a layer of zinc that provides a protective barrier against moisture and oxygen, preventing rust formation.

2. How long can galvanized steel sheets last?

With proper maintenance and installation, galvanized steel sheets can last several decades, often exceeding 50 years depending on environmental conditions.

3. Are galvanized steel sheets recyclable?

Yes, galvanized steel sheets are recyclable. The zinc coating can also be reused in the galvanizing process, making it an environmentally friendly option.

4. Can galvanized steel sheets be painted?

Yes, galvanized steel sheets can be painted, but it is essential to use appropriate primers to ensure proper adhesion to the zinc surface.

5. What are the common thicknesses of galvanized steel sheets?

Galvanized steel sheets are available in various thicknesses, typically ranging from 0.4 mm to 3 mm, depending on the specific application requirements.

PREVIOUS:

Contact Us

Phone/WhatsApp

Address

B1213 Global Centre, No.226 Zhonghua North Street, Shijiazhuang, China

WhatsApp / Wechat

TEL / FAX

Address

B1213 Global Centre, No.226 Zhonghua North Street, Shijiazhuang, China

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.