Discover the Unmatched Benefits of Using Stainless Steel Grating in Modern Construction

Dec 30,2025

Discover the Unmatched Benefits of Using Stainless Steel Grating in Modern Construction

Table of Contents

1. Introduction to Stainless Steel Grating

2. Understanding the Material: What is Stainless Steel?

3. Advantages of Stainless Steel Grating

3.1 Enhanced Durability and Longevity

3.2 Safety and Slip Resistance

3.3 Aesthetic Appeal

3.4 Corrosion Resistance

3.5 Low Maintenance Requirements

4. Com

Discover the Unmatched Benefits of Using Stainless Steel Grating in Modern Construction

Table of Contents

1. Introduction to Stainless Steel Grating

2. Understanding the Material: What is Stainless Steel?

3. Advantages of Stainless Steel Grating

3.1 Enhanced Durability and Longevity

3.2 Safety and Slip Resistance

3.3 Aesthetic Appeal

3.4 Corrosion Resistance

3.5 Low Maintenance Requirements

4. Common Applications of Stainless Steel Grating in Construction

4.1 Industrial Flooring

4.2 Walkways and Platforms

4.3 Drainage Solutions

4.5 Handrails and Guardrails

5. Installation Considerations for Stainless Steel Grating

6. Maintenance Tips for Stainless Steel Grating

7. Comparing Stainless Steel Grating with Other Materials

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Stainless Steel Grating

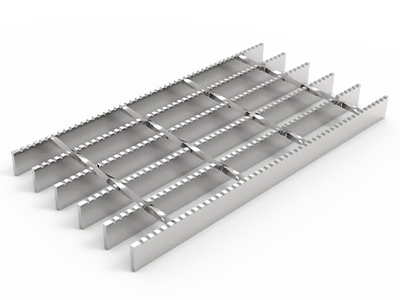

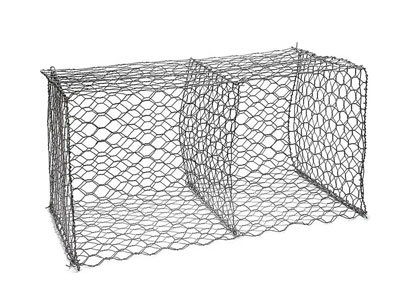

In the construction industry, **stainless steel grating** has emerged as a popular choice for various applications due to its unique properties and benefits. As a material known for its strength and resistance to various environmental factors, stainless steel grating is utilized in both commercial and industrial settings. This article delves into the myriad benefits of using stainless steel grating, highlighting its advantages, applications, and maintenance requirements while providing a comprehensive guide for construction professionals.

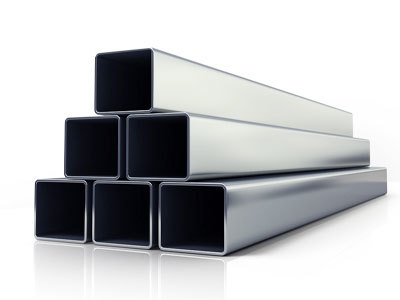

2. Understanding the Material: What is Stainless Steel?

**Stainless steel** is an alloy composed primarily of iron, with a minimum of 10.5% chromium content. The addition of chromium creates a passive layer of chromium oxide on the surface, allowing stainless steel to resist oxidation and corrosion. Because of these properties, stainless steel is the go-to material for a wide range of applications, including grating, where durability and strength are paramount.

3. Advantages of Stainless Steel Grating

The use of stainless steel grating in construction comes with several advantages, making it an ideal choice for various projects.

3.1 Enhanced Durability and Longevity

Stainless steel grating is known for its **exceptional durability**. It withstands heavy loads and extreme conditions, making it suitable for high-traffic areas, such as industrial sites or commercial buildings. Unlike other materials, stainless steel grating has a longer lifespan, reducing the need for frequent replacements and repairs.

3.2 Safety and Slip Resistance

Safety is a primary concern in construction, and stainless steel grating excels in providing slip resistance. The design of the grating allows for water drainage, preventing the accumulation of liquids that can lead to slips and falls. Many stainless steel grating options come with textured surfaces that enhance traction, making them an excellent choice for walkways, ramps, and other pedestrian areas.

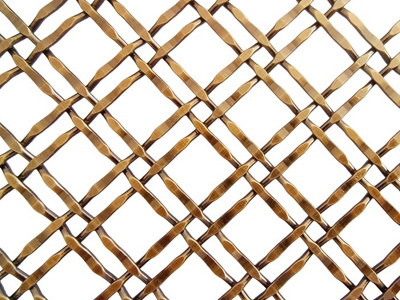

3.3 Aesthetic Appeal

Beyond functionality, stainless steel grating offers **aesthetic benefits**. Its sleek, polished finish complements modern architectural designs, enhancing the overall visual appeal of a building. With various styles and configurations available, stainless steel grating can be tailored to fit any design requirement, making it a versatile choice for both interior and exterior applications.

3.4 Corrosion Resistance

One of the most significant advantages of stainless steel grating is its corrosion resistance. This property makes it particularly suitable for environments exposed to moisture, chemicals, or harsh weather conditions. Unlike carbon steel, which can rust and degrade over time, stainless steel maintains its integrity and appearance, ensuring longevity even in challenging settings.

3.5 Low Maintenance Requirements

Stainless steel grating is **easy to maintain**. A simple rinse with water and mild detergent is usually sufficient to keep it clean. Unlike other materials that may require repainting or sealing, stainless steel grating’s resistance to rust and corrosion minimizes the need for extensive maintenance, saving both time and resources in the long run.

4. Common Applications of Stainless Steel Grating in Construction

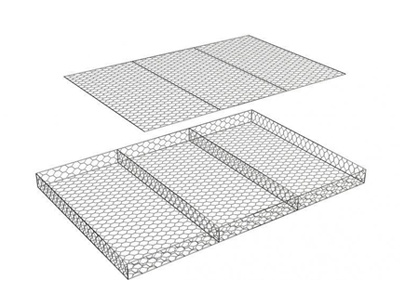

Stainless steel grating finds a wide range of applications in construction. Below are some of the most common uses:

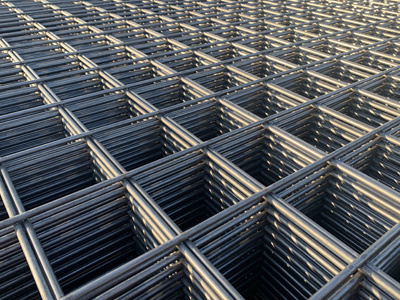

4.1 Industrial Flooring

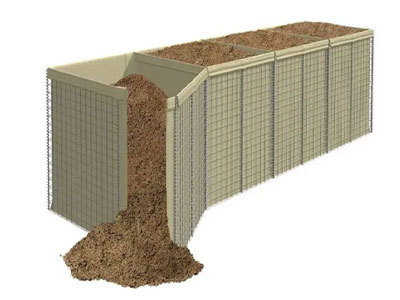

In industrial settings, stainless steel grating is often used for flooring due to its strength and durability. It provides a robust surface that can support heavy machinery and withstand wear, making it an ideal choice for factories and warehouses.

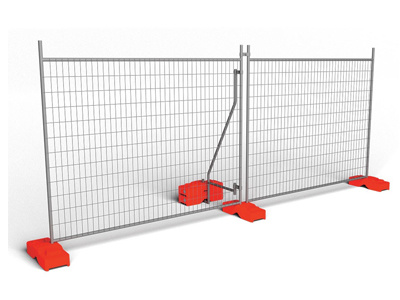

4.2 Walkways and Platforms

Stainless steel grating is widely utilized in walkways and platforms. Its slip-resistant surface ensures safety for pedestrians while allowing for easy drainage of water and debris, making it perfect for outdoor applications.

4.3 Drainage Solutions

Stainless steel grating is commonly employed in drainage systems. Its design allows for effective water flow while preventing larger debris from clogging pipes. This application is particularly valuable in urban environments where proper drainage is crucial.

4.4 Handrails and Guardrails

Stainless steel grating can also be integrated into handrails and guardrails. The material's strength ensures that these safety features can withstand significant forces while providing a modern appearance that enhances the overall design of a building.

5. Installation Considerations for Stainless Steel Grating

When installing stainless steel grating, several factors should be taken into account to ensure optimal performance and safety.

- **Load Requirements**: Assess the weight and load capacity needed for the application to choose the appropriate grating thickness and design.

- **Fastening Methods**: Various fastening options are available, including clips, screws, or welding. Select the method that best suits the specific application and environment.

- **Alignment and Leveling**: Proper alignment and leveling are crucial for ensuring safety and functionality. Careful measurements should be taken during installation to guarantee that the grating is securely in place.

6. Maintenance Tips for Stainless Steel Grating

Although stainless steel grating requires minimal maintenance, following these tips can help prolong its lifespan and appearance:

- **Regular Cleaning**: Periodic cleaning with water and mild detergent will help remove dirt and grime. For more challenging stains, a specialized stainless steel cleaner may be required.

- **Inspection**: Regularly inspect the grating for any signs of wear or damage, particularly in high-traffic areas.

- **Avoid Harsh Chemicals**: Refrain from using abrasive cleaners or harsh chemicals that may damage the surface finish.

7. Comparing Stainless Steel Grating with Other Materials

When considering grating options, it is helpful to understand how stainless steel compares to alternative materials:

- **Carbon Steel**: While carbon steel is often cheaper, it lacks the corrosion resistance of stainless steel, making it a less durable option in many environments.

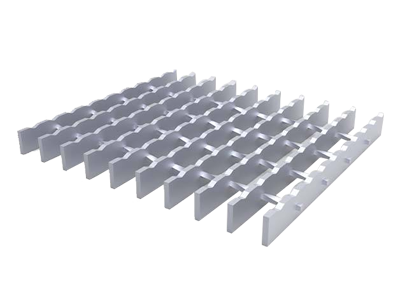

- **Aluminum**: Aluminum grating is lightweight and resistant to corrosion, but it may not provide the same load-bearing capacity as stainless steel.

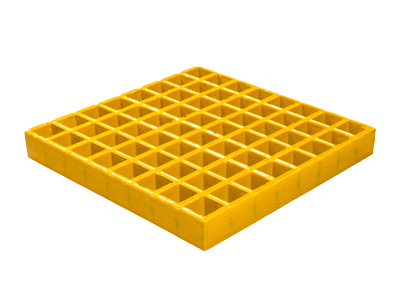

- **Fiberglass**: Fiberglass grating is non-corrosive and lightweight but typically lacks the strength and durability of stainless steel, making it unsuitable for heavy-duty applications.

8. Frequently Asked Questions (FAQs)

8.1 What is the lifespan of stainless steel grating?

The lifespan of stainless steel grating can exceed 30 years, depending on the environment and maintenance practices.

8.2 How is stainless steel grating installed?

Stainless steel grating can be installed using clips, screws, or welding, depending on the specific application and load requirements.

8.3 Is stainless steel grating suitable for outdoor use?

Yes, stainless steel grating is ideal for outdoor use due to its corrosion resistance and durability.

8.4 What are the weight capacities of stainless steel grating?

Weight capacities vary based on the thickness and design of the grating. It's essential to select the correct type based on anticipated loads.

8.5 How do I clean stainless steel grating?

Regular cleaning with warm water and mild detergent is recommended. For stubborn stains, use specialized stainless steel cleaners.

9. Conclusion

In summary, **stainless steel grating** offers numerous benefits for construction projects, including unparalleled durability, safety, aesthetic appeal, and low maintenance requirements. Its versatility in applications such as flooring, walkways, and drainage systems makes it a valuable choice for various construction needs. By understanding the advantages, installation considerations, and maintenance tips associated with stainless steel grating, construction professionals can leverage this material to enhance the quality and longevity of their projects. Embracing stainless steel grating can lead to safer, more efficient, and visually appealing construction outcomes.

TAG:

PREVIOUS:

Contact Us

Phone/WhatsApp

Address

B1213 Global Centre, No.226 Zhonghua North Street, Shijiazhuang, China