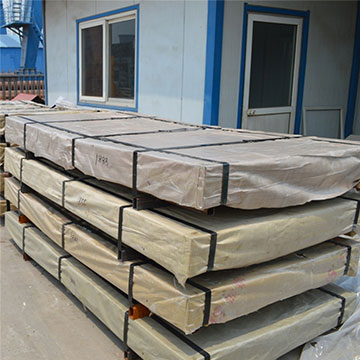

Hot rolled steel sheet Named: hot rolled plate, hot rolled plate with continuous casting slab or slab as raw material, by step heating furnace, high pressure water descaling into the roughing mill, after roughing expected by the cutting head, tail, and then into the finishing mill, and the implementation of computer controlled rolling, after finishing after laminar cooling (computer controlled cooling rate) and the winder, and became a straight hair volume.

Thickness:0.8、1.0、1.2、1.5、1.8、2.0、2.35、2.45、2.50、2.70、2.75、2.8、2.9、2.95、3.0、3.25、3.3、3.5、3.75、3.8、3.9、3.95、4、4.25、4.5、4.7、4.75、5、5.5、5.75、6、6.75、7、7.5、7.75、8、8.75、9、9.5、9.75、10、10.5、11、11.5、12mm

Width:1000/1219/1250/1500/1600/1800/2000/2200/2500mm

Lengt:100—6000mm

|

Type |

Standard |

GB STANDARD |

Standard No. |

INTERNATIONAL STANDARD CODE |

|

Low carbon stee |

Q/BQB302 |

SPHC |

JISG3131 |

SPHC |

|

SPHD |

SPHD |

|||

|

SPHE |

SPHE |

|||

|

SAE1006/SAE100 |

SAE1006/SAE1008 |

|||

|

XG180IF/200IF |

XG180IF/200IF |

|||

|

Structure steel |

GB/T912-1989 |

Q195 |

JISG3101 |

SS330 |

|

Q235B |

SS400 |

|||

|

SS400 |

SS490 |

|||

|

ASTMA36 |

SS540 |

The difference with cold rolled steel plate

Cold rolled steel plate due to a certain degree of work hardening, toughness is low, but can achieve a better flexion ratio, used for cold bending spring pieces and other parts, and because the yield point is closer to the tensile strength, so the use of the process of danger is not predictable, in the load more than allowable load prone to accidents.1) the surface of the cold plate is processed by cold binding without oxidation skin, with good quality.The surface of hot – rolled steel plate is oxidized by hot – strapping.2) hot rolled steel plate toughness and surface flatness is poor, the price is lower, while cold rolled plate stretch good, toughness, but the price is more expensive.3) rolling is divided into cold rolled and hot rolled steel plates, with recrystallization temperature as the distinguishing point.4) cold rolling: cold rolling is generally used in the production of strip, its rolling speed is higher.Hot rolled steel: the temperature of hot rolling is close to that of forging.5) the surface of non-electroplated hot tie plate is black and brown, while the surface of non-electroplated cold tie plate is gray. After electroplating, the surface can be distinguished by its smoothness. The smoothness of cold tie plate is higher than that of hot tie plate.